During production there are many points which have the potential to create wastage. The more steps we add to the production, the more this is amplified. Keeping record of it all, if you can, can be a time consuming process. If we add the tracking of rework, this adds a whole other layer of complication.

With Fusion Operations, we not only have controls which let us to track and report on wastage, but ones that allow us to track recoverable materials or products as well.

Recording

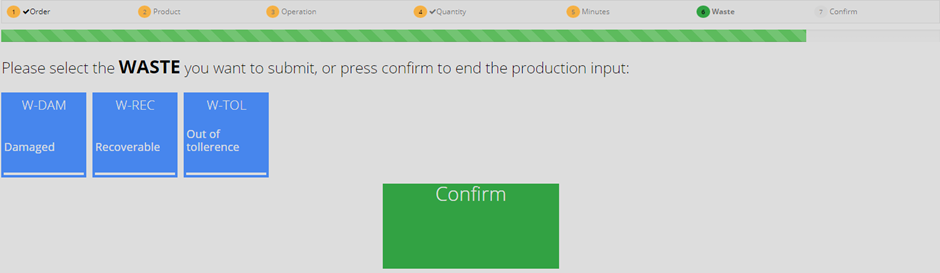

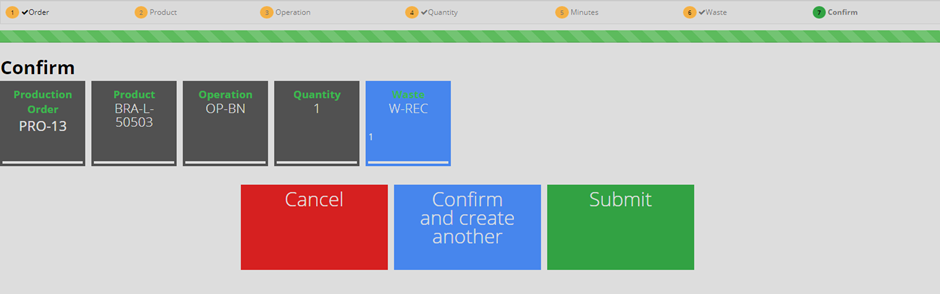

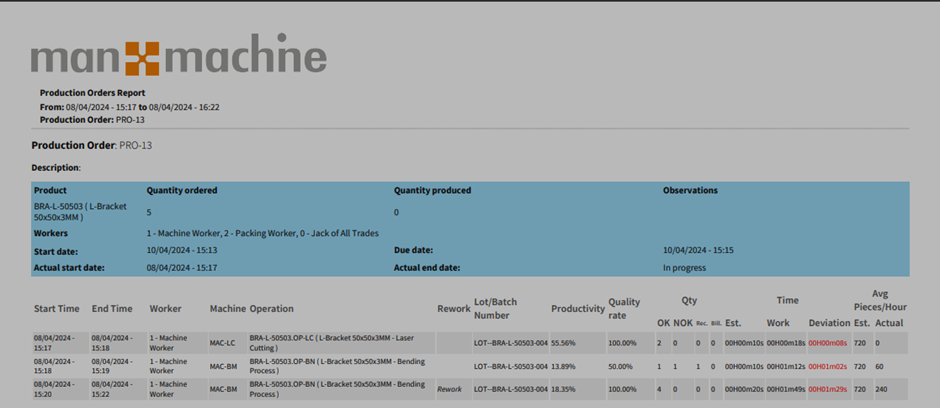

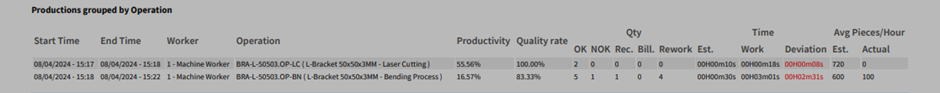

Every operation in your production workflow has the ability to track waste. Giving workers the ability to input this information as this occurs. This also allows us to narrow down which operations we allow rework at, giving us more control over the quality of the outputs.

Reporting

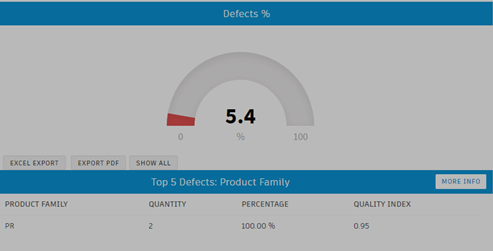

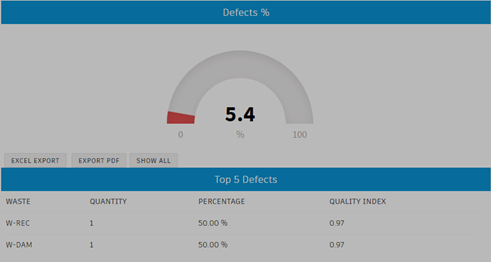

Using the data input by the machine operators, we can start to generate reports from the waste that is created during production. This will not only help validate our company wide quality, but allow us to narrow down to individual products, or operations. Giving us a great tool to determine processes that require further attention, or adjustment. Gathering this data at the source also ensures a more accurate picture, while capturing live data.

Looking at the Company Wide quality meter, we get live feedback as to the quality of our outputs at each stage.

The wastage or defects can be reported against. Here we can break them down into Product Families, or Waste type.

We can also report this for each production order to get a better understanding of the costs associated with each order.

For more information on this blog post, or if you have any other questions/requirements, please complete the below form: